A grease gun is a typical lubricating item used in garages and workshops. The purpose of grease guns is to inject lubricating grease into machinery with moving parts. Three main parts are often found in grease guns: a cylinder, a propulsion control, and a delivery mechanism. Read More…

Established in 1997, Acumen Technologies, Inc. has been a trusted manufacturer of a high quality chain oiler for fifteen years. Our experienced employees are very knowledgeable and ready to answer any questions you may have about lubricating products and equipment. We seek to create products that solve lubrication problems you may be having. Contact us today and let us know how we can serve you!

Our grease pumps cannot be topped! Since we were established we have been providing our customers with an extensive line of lubrication systems equipment that will stand up the rigorous wear and tear of everyday application in order to provide a lifetime of value. We have been providing our customers exceptional customer service and this is a tradition that we strive to continue. Visit our...

Automatic lubricating systems, lubrication equipment, bulk grease transfer systems, pumps and other lubricating machinery are available through us. We design and manufacture lubrication systems and make repairs. We distribute specialty lubricants, chain lubricators and other lubrication products.

North American manufacturer and distributor of meters and systems designed for monitoring circulating oil lubrication and grease distribution. Product types include variable area flow meters, oval gear flow meters, grease pumps, dosers and flow sensors. ESKO meters are available in multi-flow configurations of up to 12 meters in a bank. Lubrication monitoring systems can be furnished in custom...

Are you looking for variety and ease in ordering? Then you've come to the right place... D & D Instruments. We offer automotive oil gauges and vacuum gauges. We also provide pressure process gauges. We furnish extensive on-line ordering so you can order just the right product for your application.

More Grease Gun Manufacturers

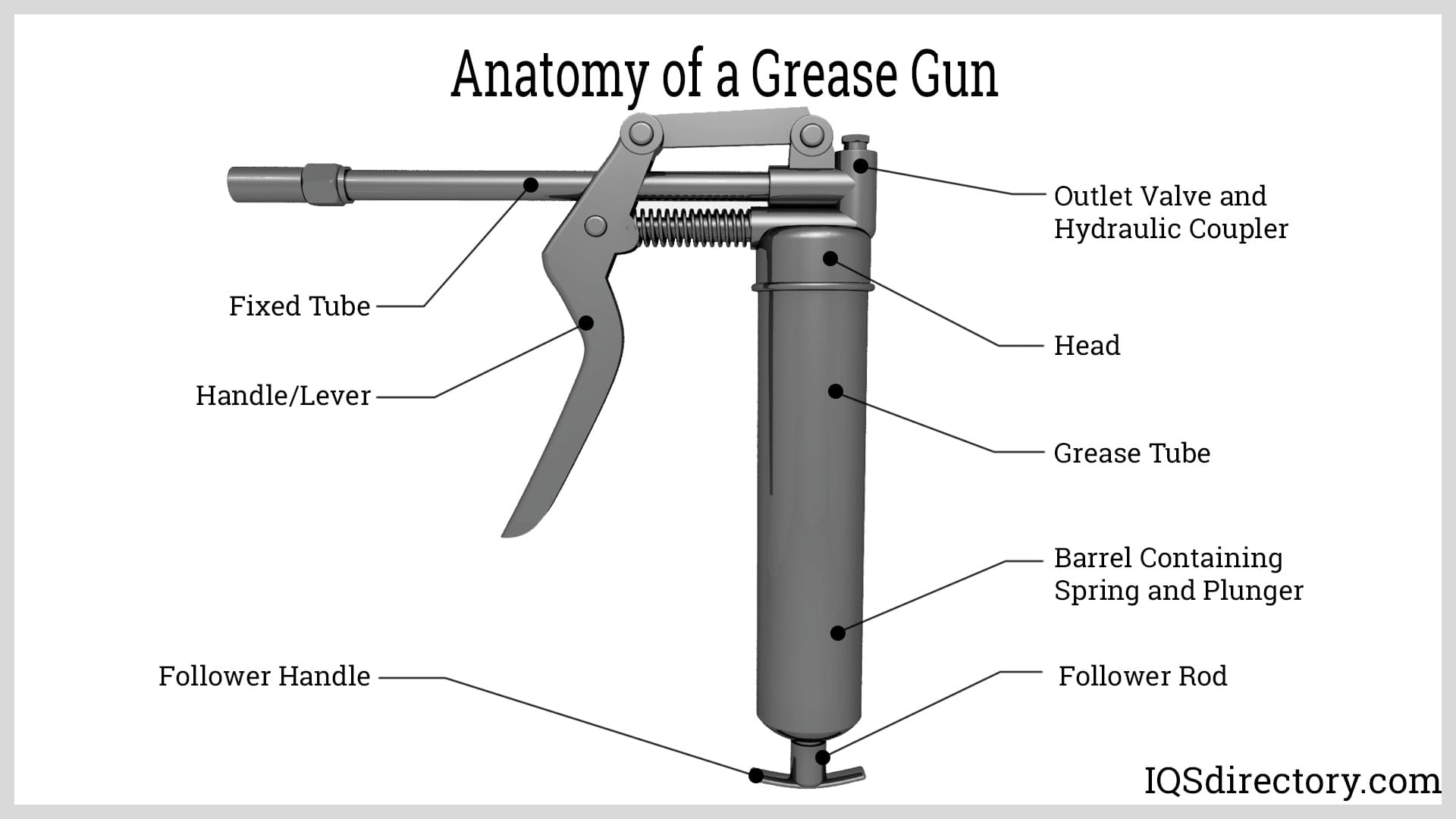

First, the component of the grease gun that holds the grease is the metal cylinder. Next, the user uses a level or trigger as the propulsion control to regulate grease flow. Finally, a coupler-equipped flexible hose or rigid metal tube will most frequently be used as the delivery device. These products are battery, pneumatic, or manually operated.

Anatomy of a Grease Gun

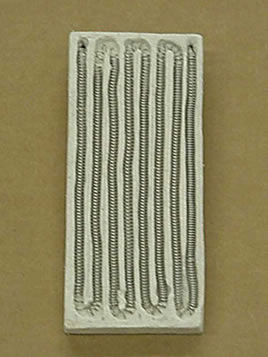

In manual grease gun setups, the lever is utilized to manually pump grease from the barrel to the hose or tube. Like the lever, the trigger and handle of the grease gun's manual versions are used to manually pump grease from the barrel to the hose or tube. The grease gun's exoskeleton, the barrel, is where the grease tube or grease from bulk storage is stored. When the grease inside the grease tube (or cartridge) runs out, it can be swapped out for a new one. The hydraulic coupler (or connector) is the point of attachment for the tube or hose attached to the grease gun's head. Grease paths and valves in the grease gun's head enable grease to be pumped from the barrel into a flexible hose or fixed tube. A grease from a filler pump is injected at the filler nipple. After fresh oil has been loaded into the grease gun and pumped into the head, air can escape through the air-release nipple. The plunger is under pressure, thanks to the spring.

As it maintains pressure on the grease tube's lower end, the follower rod (also known as a piston rod, barrel rod, or plunger rod) aids the plunger's ability to follow a straight route. Additionally, it works to retract the spring before a fresh grease tube is inserted. The follower handle provides a hold when removing the follower rod before installing a new grease tube. The plunger applies consistent pressure to the grease tube's back end as grease is used up. For a flexible connector or coupler location, the flexible hose can be utilized in place of a fixed tube. A flexible hose in a hard shape is what the fixed tube is.

Types of Grease Guns

There are three ways to power grease guns: by hand, air, or electricity. The advantages of each of them depend on the intended use and the preference of the lubrication professional.

Hand Pumps

The grease supplied by hand pumps is driven via an aperture in this type of grease gun, which is the most prevalent and has a grease capacity of 1.28 grams per pump.

This variant of the grease cannon with a lever enables the widely used one-handed pumping technique. Per pump, it delivers about 0.86 grams.

Electric Powered

They do not require manual operation to pump the grease and are suitable for constant use since they don’t expend an operator’s energy. Instead of relying on human power, electric powered grease guns use batteries as their power source.

Pneumatic (Air)

Each trigger on this grease pistol activates a positive displacement by using pressurized air directed into the gun by a hose.

Grease Gun Advantages

The real benefit of a grease gun is that it allows the user to apply lubricant to a machine without contaminating it with unintended particles. This product is also excellent at preventing contamination of the lubricant itself in desired areas. For these goods to work effectively, specialist nozzles may occasionally be needed. It's also crucial to remember that frequent over-lubrication may harm the machine.

Grease Gun Best Practices

Based on the calibrated delivery volume of the chosen grease cannon, determine the correct quantity of grease required for relubricating bearings. Use a vent plug on the relief port to wash out old grease and lessen the possibility of putting too much strain on the bearing. Load grease into the grease gun with extreme caution to prevent the introduction of impurities. When using a cartridge, do not introduce any metal slivers into the grease by hastily removing the metal cap. Ensure that the grease gun is marked to indicate the type of grease with which it should be charged. Use only the specified grease; do not use any other kind. Whenever utilizing a grease gun, make sure the distributing nozzle is clean. Before connecting the dispensing nozzle to the grease fitting, pump a tiny amount of grease out of it and clean it off with a clean rag or lint-free cloth.

Before installing the grease gun, thoroughly clean the grease fitting. Examine and repair any broken fittings. While grease-fitting caps are useful for keeping fittings clean, fittings should still be cleaned before applying grease. Check to make sure the right grease is applied at each grease spot. The incorrect grease application can result in an incompatibility issue, swiftly leading to bearing failure. In addition, it should be apparent which grease will be used at each lubrication site. This identification can be done using colorful labels, sticky dots, or paint markers. Grease guns should be stored unpressurized in a clean, cold, and dry place and in a horizontal position to prevent the oil from seeping out of the grease. Storage is made simple and tidy with grease gun clamps. Cover the coupler as well to protect it from pollutants and dirt. Finally, regularly calibrate grease guns to ensure the correct distribution volume.

Choosing the Right Grease Gun Supplier

To ensure you have the most positive outcome when purchasing grease guns from a grease gun supplier, it is important to compare several companies using our directory of grease gun suppliers. Each grease gun supplier has a business profile page highlighting their areas of experience and capabilities, and a contact form to directly communicate with the supplier for more information or request a quote. Review each grease gun company website using our proprietary website previewer to quickly learn what each business specializes in, Then, use our simple RFQ form to contact multiple grease gun companies with the same form.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches