Lubricant is fed into the tubing system of the automatic centralized lubrication system by lubrication pumps from the lubricant reservoir. There are various types of lubrication pumps, including gear and barrel pumps. Read More…

Established in 1997, Acumen Technologies, Inc. has been a trusted manufacturer of a high quality chain oiler for fifteen years. Our experienced employees are very knowledgeable and ready to answer any questions you may have about lubricating products and equipment. We seek to create products that solve lubrication problems you may be having. Contact us today and let us know how we can serve you!

Our grease pumps cannot be topped! Since we were established we have been providing our customers with an extensive line of lubrication systems equipment that will stand up the rigorous wear and tear of everyday application in order to provide a lifetime of value. We have been providing our customers exceptional customer service and this is a tradition that we strive to continue. Visit our...

Automatic lubricating systems, lubrication equipment, bulk grease transfer systems, pumps and other lubricating machinery are available through us. We design and manufacture lubrication systems and make repairs. We distribute specialty lubricants, chain lubricators and other lubrication products.

North American manufacturer and distributor of meters and systems designed for monitoring circulating oil lubrication and grease distribution. Product types include variable area flow meters, oval gear flow meters, grease pumps, dosers and flow sensors. ESKO meters are available in multi-flow configurations of up to 12 meters in a bank. Lubrication monitoring systems can be furnished in custom...

Are you looking for variety and ease in ordering? Then you've come to the right place... D & D Instruments. We offer automotive oil gauges and vacuum gauges. We also provide pressure process gauges. We furnish extensive on-line ordering so you can order just the right product for your application.

More Lubrication Pump Manufacturers

What is a Gear Oil Pump?

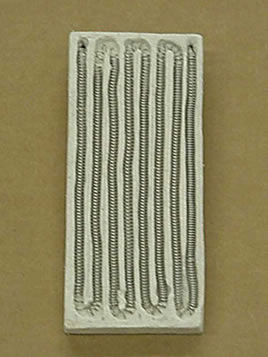

A horizontal slewing gear pump circulates gear oil. Gear pumps are categorized as Diesel-driven or motor-driven. Gear pumps can transport oils and other lubricated medium liquids, as long as the liquid temperature is below 60°C. However, gear pumps are inappropriate for media solutions containing significant sulfur, corrosives, hard particles, and fibers. Additionally, extremely flammable, low-flashing medium liquids like gasoline, benzene, etc., should not be transported using gear pumps.

A gear oil pump is made of gears, shafts, pump bodies, pump covers, bearing sleeves, shaft end seals, and other parts. The gears and shafts have high hardness and are wear-resistant because of strict heat treatment when put in the bushing with the shaft. They deliver lubricant for all functional elements in the pump. The surface residual oil pump has hard teeth. The pump has four bearing sleeves. The end-face interval of the sleeves changes automatically based on the working pressure. Because of a minimal output flow pulse and great volumetric efficiency, the pump's pressure remains stable. The gear oil pump is an essential component of the high-pressure system.

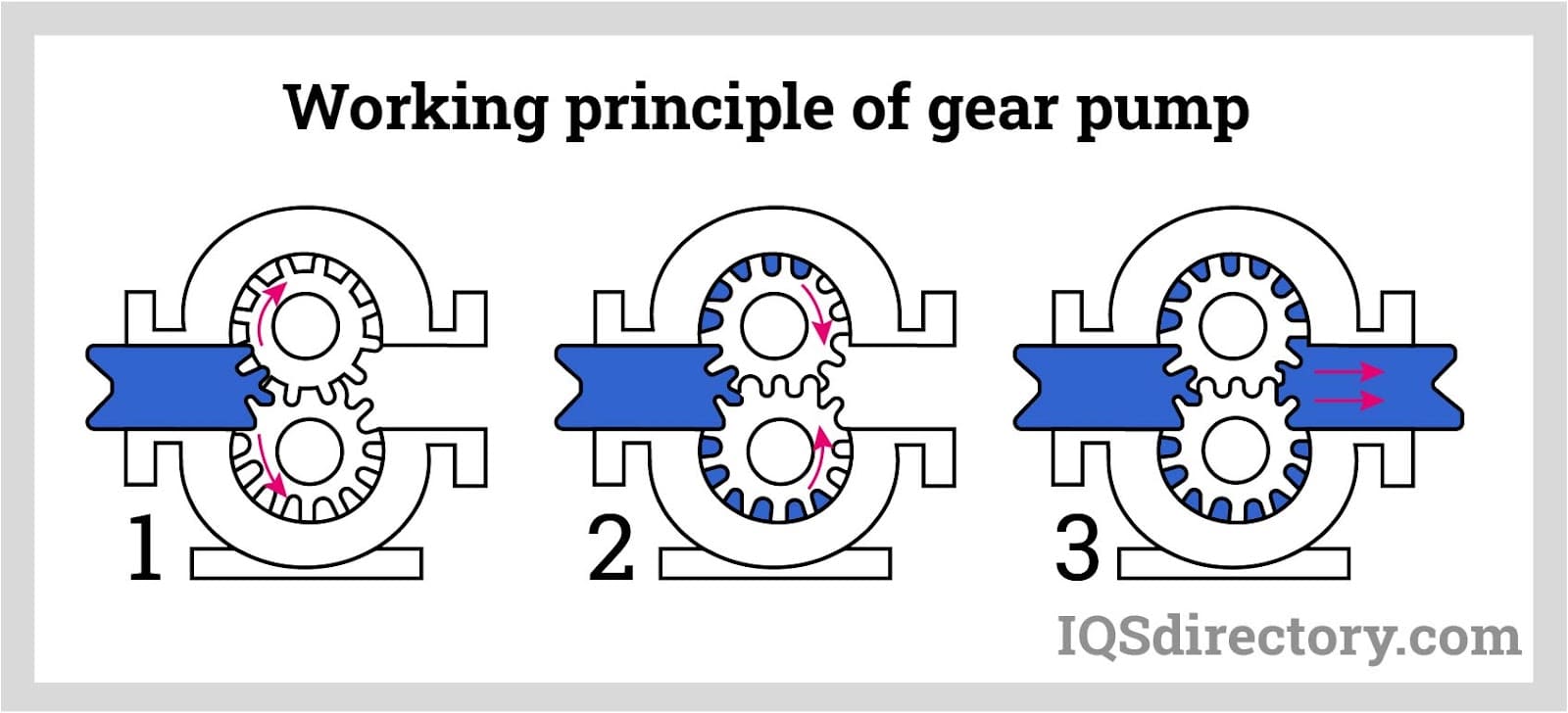

How a Gear Oil Pump Functions

Internal and external gear pumps produce flow when two gears enter and exit a mesh, a common feature of both pumps. The external gear pump uses two identical gears moving in opposition to one another, one of which is powered by a motor, which then drives the other gear. A bearing shaft on either side of the gear supports each gear.

The volume on the pump's input side expands as the gears come out of the mesh. As the gear teeth revolve, liquid flows into the cavity and is trapped there. While liquid does not pass between the gears, it moves around the interior between the teeth and the casing. Finally, pressure is applied to the outlet port due to meshing gears.

Advantages of Gear Pumps

- High speed

- High pressure

- No overhung bearing loads

- Quiet operation

- Design accommodates a wide variety of materials

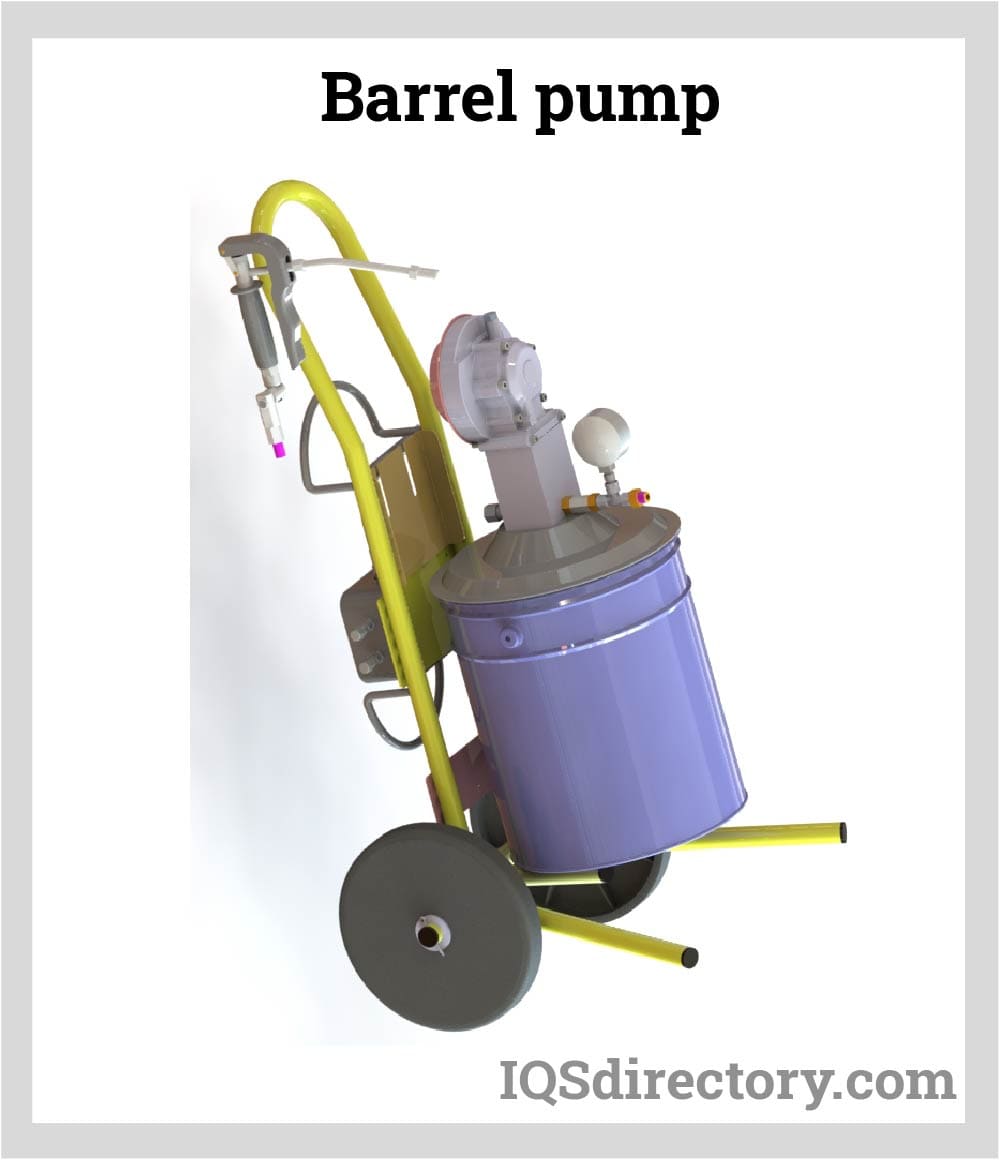

What is a Barrel Pump?

A barrel pump is a lubricating pump that works best in medium or heavy-duty service circumstances. A quick build-up of lubricating system pressure is required in air-operated central stations or bulk lubricant transfer; air-operated barrel pumps are used. Lubricants often move from the original refinery drums to the reservoirs on the central lubrication systems using air-operated barrel transfer pumps. Barrel pumps are made with high-alloy components, corrosion-resistant parts, and high-quality seals, making them highly effective with less noise and air consumption. Barrel pumps are available in 8, 10, and 16 GPM.

How a Barrel Pump Works

A barrel pump is made of an immersion tube, a motor section, and a pump section. The motor is positioned on top of the immersion tube’s exterior. The immersion tube is as long as the container. This tube is deep and sealed to an opening on top of the container and fits through this opening. Depending on the lubrication, several material constructions and tube lengths are offered to accommodate varying container depths. The pump section is situated at the bottom of the immersion tube. The pump's expanded shaft is housed in a sealed column, driven from the top of the immersion tube. The pumped liquid travels to the discharge port between the sleeve and the tube.

Applications of barrel pumps

- Industrial chemistry and research labs

- Petroleum sector

- Water treatment

- Textiles bleach

- Power facilities

- Hospitals

Barrel pumps are designed to fit a certain type of container. For instance, the immersion tube might need to be longer to drain another container since it couldn't get to the bottom of it. The ability to exchange parts makes repurposing barrel pumps simple. Barrel pumps designed for a certain fluid may not discharge another due to a difference in viscosity or chemical incompatibility.

Benefits of barrel pumps

The main benefit of a barrel pump is it reduces risks associated with handling containers manually. It simplifies handling spills, leaks, hazardous gases, and accidents. In addition, pumps for barrels are portable and lightweight, making it simple to move them between containers.

Choosing the Proper Lubrication Pump Manufacturer

To make sure you have the most productive outcome when purchasing Lubrication Pumps from a Lubrication Pump Manufacturer, it is important to compare at least 5 Companies using our list of Lubrication Pump manufacturers. Each Lubrication Pump Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Lubrication Pump business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Lubrication Pump businesses with the same message.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches