Proper lubrication is important because without it there are many ill-effects such as higher than normal wear and tear, decreased machine accuracy and decreased production efficiency. As a result, lubricants are essential to maintaining efficiency and decreasing costs. Read More…

Established in 1997, Acumen Technologies, Inc. has been a trusted manufacturer of a high quality chain oiler for fifteen years. Our experienced employees are very knowledgeable and ready to answer any questions you may have about lubricating products and equipment. We seek to create products that solve lubrication problems you may be having. Contact us today and let us know how we can serve you!

Our grease pumps cannot be topped! Since we were established we have been providing our customers with an extensive line of lubrication systems equipment that will stand up the rigorous wear and tear of everyday application in order to provide a lifetime of value. We have been providing our customers exceptional customer service and this is a tradition that we strive to continue. Visit our...

Automatic lubricating systems, lubrication equipment, bulk grease transfer systems, pumps and other lubricating machinery are available through us. We design and manufacture lubrication systems and make repairs. We distribute specialty lubricants, chain lubricators and other lubrication products.

North American manufacturer and distributor of meters and systems designed for monitoring circulating oil lubrication and grease distribution. Product types include variable area flow meters, oval gear flow meters, grease pumps, dosers and flow sensors. ESKO meters are available in multi-flow configurations of up to 12 meters in a bank. Lubrication monitoring systems can be furnished in custom...

Are you looking for variety and ease in ordering? Then you've come to the right place... D & D Instruments. We offer automotive oil gauges and vacuum gauges. We also provide pressure process gauges. We furnish extensive on-line ordering so you can order just the right product for your application.

More Grease Dispenser Manufacturers

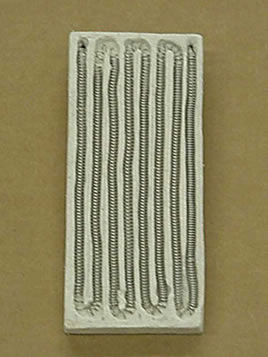

Grease, one of the more common lubricants, works exceptionally well for machinery that does not need to be lubricated too frequently. Because grease is such thick and viscous oil it will stay in positions that liquid oil from an oil dispenser would not. Formed from a mixture of oil and soap, various additives can be introduced into the mixture to develop desired characteristics. For instance, Teflon is a possible additive to grease that produces enhanced lubrication properties.

Commonly seen in the automotive industry, grease dispensers are essential in a wide range of industries including industrial manufacturing, for the lubrication of various process and assembly machinery; pharmaceutical, for use in research laboratories for the lubrication of glassware such as stopcocks and ground glass joints; food and beverage, for the lubrication of processing and packaging equipment; and construction, to lubricate various equipment and supplies such as hand-operated power tools.

Grease functions as a shear-thinning lubricant, meaning that its viscosity is reduced under shear, which is defined as stress that is applied in a parallel or tangential manner rather than normal stress, which is applied in a perpendicular method. When a sufficient level of shear is achieved, the viscosity of the grease drops and becomes similar to that of liquid oil, thus functioning as a lubricant.

Grease dispensers generally consist of three essential components: a pump, a gear set and some kind of control system or feature. Most grease dispensers have a motor, but since they can be powered in a couple of different manners including manual, electromechanical and pneumatic, they could also be powered through a hand-lever.

In terms of what kind of pump is used, grease dispensers often use a positive displacement pump, which functions by trapping a fixed amount of grease and then forcing it into the feed lines. The grease is taken from the reservoir, which is a container that stores the grease until it is needed to be dispersed or once the grease has left and returned again from area of lubrication.

Grease dispensers can feed one or more areas of lubrication. Grease dispensers that have a single point of lubrication are used on small machine applications, while grease dispensers with multiple points of lubrication are used for medium to large sized machines.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches