A grease pump is an apparatus used to apply grease to industrial machinery. Grease pumps are used in manufacturing and automotive applications. Smaller pumps can transport a few pounds of grease, whereas larger units hold up to 400 pounds. Where oil is not permitted, grease is a common alternative lubricant. Grease is applied where oil may leak and impact other parts of the machinery, building, or construction site. Read More…

Established in 1997, Acumen Technologies, Inc. has been a trusted manufacturer of a high quality chain oiler for fifteen years. Our experienced employees are very knowledgeable and ready to answer any questions you may have about lubricating products and equipment. We seek to create products that solve lubrication problems you may be having. Contact us today and let us know how we can serve you!

Our grease pumps cannot be topped! Since we were established we have been providing our customers with an extensive line of lubrication systems equipment that will stand up the rigorous wear and tear of everyday application in order to provide a lifetime of value. We have been providing our customers exceptional customer service and this is a tradition that we strive to continue. Visit our...

Automatic lubricating systems, lubrication equipment, bulk grease transfer systems, pumps and other lubricating machinery are available through us. We design and manufacture lubrication systems and make repairs. We distribute specialty lubricants, chain lubricators and other lubrication products.

North American manufacturer and distributor of meters and systems designed for monitoring circulating oil lubrication and grease distribution. Product types include variable area flow meters, oval gear flow meters, grease pumps, dosers and flow sensors. ESKO meters are available in multi-flow configurations of up to 12 meters in a bank. Lubrication monitoring systems can be furnished in custom...

Are you looking for variety and ease in ordering? Then you've come to the right place... D & D Instruments. We offer automotive oil gauges and vacuum gauges. We also provide pressure process gauges. We furnish extensive on-line ordering so you can order just the right product for your application.

More Grease Pump Manufacturers

Grease is a non-liquid lubricant, which blends soap and oil, and has a higher viscosity than oil. Grease pump designs can adapt to various grease points and grease consistencies used in industrial facilities. Every grease point may need a different amount and consistency; therefore, manufacturers should consider all available pump options to avoid using excess grease.

Types of Grease Pumps

Air Operated Grease pumps

Air-operated grease pumps use compressed air to power the air compressor. This activates the grease pump to extract the butter and then pressurizes the butter into the oil injection hole. This requires upkeep and lubrication with the grease gun. The operation is also very straightforward, making it the first choice for many industries that need lubrication, including transportation, ports, building, power, chemical, auto repair, and metallurgy industries.

Pneumatic grease pump

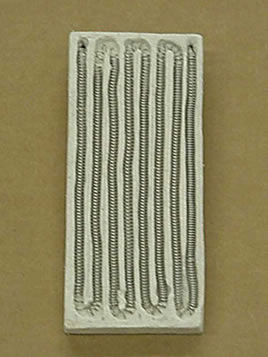

Numerous systems for lubricating things with grease or other substances can employ pneumatic pumps. A pneumatic grease pump must produce constant air pressure to force thick grease through the lines. Most pumps have an oil-resistant rubber gasket and a light alloy piston. The hardening and lapping of this steel piston lower the possibility of damage as it circulates grease throughout a system.

A steel body encases the piston. While some pumps are small and can be mounted on machinery easily, others are huge and need their place on the shop floor. A pneumatic pump is a fantastic alternative if one already has compressed air available in their facility or equipment. Additionally, if there is already an air compressor, these lubrication pumps use less electricity.

Electric grease pump

An electric grease pump is made of a stainless steel or transparent reservoir, metering devices, and a control system. Larger machines may include a pre-filling system to supply oil to the pumps from a central place. The oil reservoir is transparent, so operators can quickly determine how much oil is available. A filter ensures that only pure lubricant reaches the reservoir. A rubber plunger seal above the lubricant prevents air from entering the pumping system.

Hydraulic Grease Pump

The optimal option for a central lubrication system is a hydraulic grease pump if the equipment already has a hydraulic circuit. These pumps deliver grease to grease spots in the machinery, and they can be linked to a conventional hydraulic line to use the power already present. Although it is used in other industries, the mining sector uses hydraulic grease pumps the most.

Benefits of Grease pumps

- Effective lubrication: Manual grease guns are labor and time intensive. Instead of wasting critical time and effort lubricating every piece of equipment, employ a multi-point central lubrication system to apply the right amount of grease to every spot that needs it.

- Superior holding capacity: Manufacturers can keep hundreds of pounds of grease in a reservoir. This function alone can save the maintenance crew much time.

- A centralized system allows manufacturers to add oxidation inhibitors and anti-wear compounds to the grease. These additives extend the grease's shelf life and minimize abrasion.

- Cost-effective performance: A grease pump system can be a fantastic way for any organization to cut costs after making the initial investment. Not only will time be saved, but daily operations will require less grease.

What to Consider When Selecting Grease Pumps

Manufacturers should analyze how much grease is required for each grease point in the machinery or facility. Additionally, it's important to count the grease points and measure their separation from one another. This information will be used to calculate the system pressure needed to adequately lubricate the equipment's essential locations.

Choosing the Proper Grease Pump Manufacturer

To ensure the most beneficial outcome when purchasing grease pumps from a grease motor manufacturer, it is important to compare several companies using our directory of grease pump manufacturers. Each grease pump manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each grease pump business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple grease pump companies with the same form.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches