Lubrication equipment is described as a controlled and exact delivery system of a particular lubricant to a particular area at a particular time while the machine is operating. Read More…

Established in 1997, Acumen Technologies, Inc. has been a trusted manufacturer of a high quality chain oiler for fifteen years. Our experienced employees are very knowledgeable and ready to answer any questions you may have about lubricating products and equipment. We seek to create products that solve lubrication problems you may be having. Contact us today and let us know how we can serve you!

Our grease pumps cannot be topped! Since we were established we have been providing our customers with an extensive line of lubrication systems equipment that will stand up the rigorous wear and tear of everyday application in order to provide a lifetime of value. We have been providing our customers exceptional customer service and this is a tradition that we strive to continue. Visit our...

Automatic lubricating systems, lubrication equipment, bulk grease transfer systems, pumps and other lubricating machinery are available through us. We design and manufacture lubrication systems and make repairs. We distribute specialty lubricants, chain lubricators and other lubrication products.

North American manufacturer and distributor of meters and systems designed for monitoring circulating oil lubrication and grease distribution. Product types include variable area flow meters, oval gear flow meters, grease pumps, dosers and flow sensors. ESKO meters are available in multi-flow configurations of up to 12 meters in a bank. Lubrication monitoring systems can be furnished in custom...

Are you looking for variety and ease in ordering? Then you've come to the right place... D & D Instruments. We offer automotive oil gauges and vacuum gauges. We also provide pressure process gauges. We furnish extensive on-line ordering so you can order just the right product for your application.

More Lubrication Equipment Manufacturers

The reasons for lubricating are to reduce the following:

- friction and wear of components

- energy and lubricant consumption

- The generation of heat

- The noise from friction

- Damage due to corrosion and avoiding the insertion of contaminants at the work site.

Types of lubricating systems

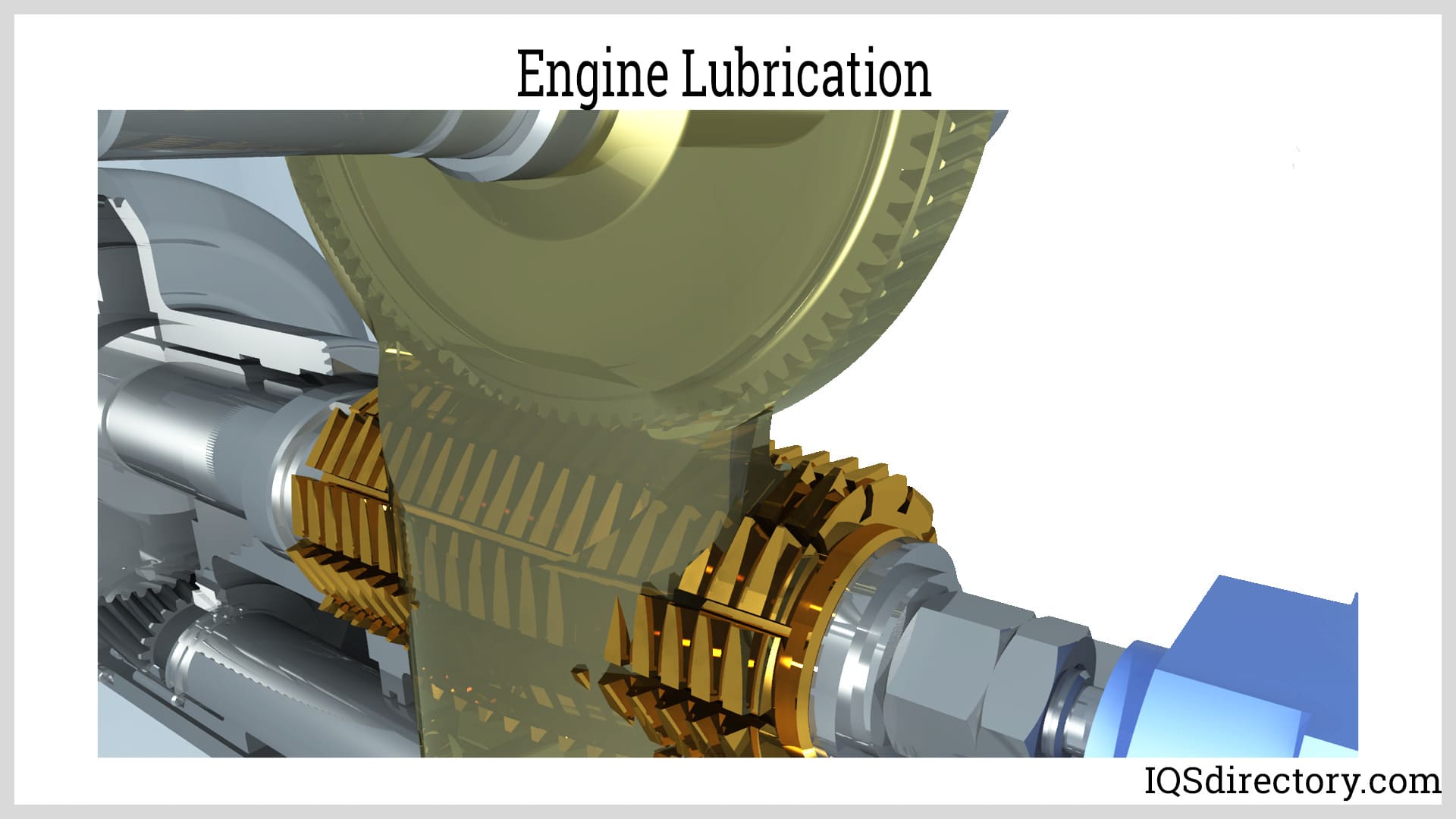

Oil lubrication system

Another name for the oil lubrication system is the loss lubrication system. Oil or liquid grease creates a thin oil layer that shields the parts in this system. An automatic lubrication system with an electric oil pump replaces it regularly. Single-line and 33V systems are the two primary oil lubrication systems.

Air Oil lubrication system

In this technique, small amounts of air oil particles are cooled and transported to the lubricating sites by a controlled stream of air oil. It can be used by large machines in heavy industry and machine tools. For example, an air oil lubrication system is ideal for reliable and affordable bearings lubrication. High production availability is also obtained because the bearings have a longer service life.

Grease lubrication system

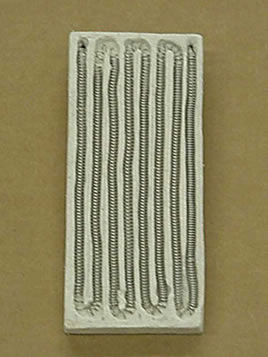

Greasing pumps in this system distribute the necessary grease to the lubrication locations. Dual lines and progressive systems are the two primary grease lubrication systems.

Progressive lubrication system

The best lubrication system for small to medium-sized equipment that requires continuous lubrication is a progressive lubrication system. Progressive systems offer continuous lubrication as long as the pump is operating. When the pump is turned off, the pistons of the progressive metering device will stop moving at their current location. As soon as the pump starts to provide oil once more, the pistons will move back to their normal locations.

Wet sump system

Wet sump lubrication systems use a sump filter to deliver oil to various engine components, and the oil pressure in these systems ranges from 4 to 5 kg/cm2. The oil is once more sent to the oil sump after lubrication. In this instance, the sump contains the oil. It is referred to as a wet sump lubrication system as a result. The simplicity of the wet sump system is an advantage. There aren't many parts needed; the machine parts are close to the area where lubricating oil will be applied for lubrication, and making the machine in the car is generally safe.

Dry sump system

In addition to the wet-sump lubrication system, a dry-sump lubrication system is frequently utilized in racing automobiles. A breather tank and an oil tank are among these components. The dry-sump lubrication also includes a multi-stage pump and cyclone separator. To maximize the benefits of lubrication, we have discussed several lubrication systems utilized in various applications. The automatic lubrication system has numerous features in addition to maximizing benefits.

Considerations When Choosing a Lubrication System

- Lubricant types: oil or grease and its features

- Lubrication types: total loss, air-oil, grease, recirculating oil

- Lubrication points: number, position, type

- Amount of lubricant to be applied per single point or defining the proportionality between the points.

- Supply type: manual, electric, and pneumatic

- Management type: manual, automatic with or without electrical control panel

- Specific condition: temperature

Benefits of using lubrication systems

- Easy access: Regardless of location or importance, the machine's vital parts can all be oiled. This guarantees safe machine operation and lowers the possibility of maintenance staff using undefined lubrication components.

- Increased machine efficiency: In a centralized lubrication system, lubrication occurs while the machine operates, distributing the lubricant equally across all friction points and improving overall machine performance, reducing breakdown, downtime, and replacement costs.

- Reduced energy consumption: With centralized or automatic lubrication, the lubricant is delivered to the friction point at the proper time and in the proper quantity, resulting in minimal friction, decreased energy consumption, and lower total machine operating costs.

- Cleanliness: Lubricant contamination caused by foreign particles affects overall performance and life. For every maintenance worker, preventing grease contamination in manual lubrication systems can be difficult. However, we can prevent lubricant contamination and ensure cleanliness by using an autonomous lubrication system. An automatic lubricant can deliver a continuous, precise flow of new, clean lubricant at the lubrication sites in an automatic lubrication system.

- Near dry machining: This cutting-edge new technology takes the place of conventional, pure oil-liquid systems. Minimal cutting oil is delivered to the cutting surface in an aerosol format by external or internally regulated compressed air flow through equipment lubrication. Near dry machining falls within a smaller tent than MQL, which is minimum quality lubrication. MQL can be used in various production processes, including sheet metal forming, blanking, shaping, cutting, and many more. The term "near dry machining" refers more specifically to machining processes, including milling, drilling, turning, and tapping.

Choosing the Right Lubrication Equipment Supplier

To ensure the most constructive outcome when purchasing lubrication equipment from a lubrication equipment supplier, it is important to compare several companies using our directory of lubrication equipment suppliers. Each lubrication equipment supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each lubrication equipment business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple lubrication equipment companies with the same form.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches