Moving or rotating parts of machinery, such as dies, chains, spindles, pumps, cables, rails, bearings and gears, need to be lubricated in order to run smoothly and reliably. Read More…

Established in 1997, Acumen Technologies, Inc. has been a trusted manufacturer of a high quality chain oiler for fifteen years. Our experienced employees are very knowledgeable and ready to answer any questions you may have about lubricating products and equipment. We seek to create products that solve lubrication problems you may be having. Contact us today and let us know how we can serve you!

Our grease pumps cannot be topped! Since we were established we have been providing our customers with an extensive line of lubrication systems equipment that will stand up the rigorous wear and tear of everyday application in order to provide a lifetime of value. We have been providing our customers exceptional customer service and this is a tradition that we strive to continue. Visit our...

Automatic lubricating systems, lubrication equipment, bulk grease transfer systems, pumps and other lubricating machinery are available through us. We design and manufacture lubrication systems and make repairs. We distribute specialty lubricants, chain lubricators and other lubrication products.

North American manufacturer and distributor of meters and systems designed for monitoring circulating oil lubrication and grease distribution. Product types include variable area flow meters, oval gear flow meters, grease pumps, dosers and flow sensors. ESKO meters are available in multi-flow configurations of up to 12 meters in a bank. Lubrication monitoring systems can be furnished in custom...

Are you looking for variety and ease in ordering? Then you've come to the right place... D & D Instruments. We offer automotive oil gauges and vacuum gauges. We also provide pressure process gauges. We furnish extensive on-line ordering so you can order just the right product for your application.

More Lubricating System Manufacturers

Many different types of lubricating systems may be used in the same industrial plant in order to keep the assembly line moving without hitch. To ensure effective operation, most moving parts require regular lubrication. Thankfully, there is a vast variety of lubricating systems to ensure that every piece of machinery is thoroughly lubricated.

Air lubricators, for instance, supply lubrication and filtration to compressed air lines. These lubricators are often built into the line itself, providing constant lubrication to power tools and other mechanisms. Chain oilers, on the other hand, are units that dispense measured amounts of lubricant along the length of a chain or rail. Both of these systems can be automatic, running by way of preset programs rather then individual manual attention.

Such systems are cost effective and more productive, and therefore very popular in the industry. Another automatic system is the central lubrication. This system, which also often attaches itself to the machine it lubricates, is able to cover more then one part of a machine at once. Other systems include gas pumps and constant level oilers.

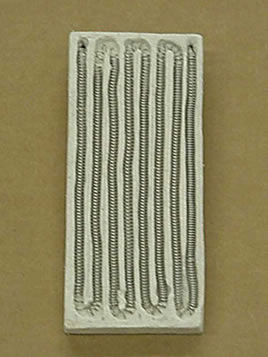

The two major types of lubrication employed by these systems are grease and oil. Grease is a semisolid lubricant that in essence is a combination of mineral or vegetable oil and soap, not animal fat like other types of grease. They are utilized in industries that require infrequent lubrication of machines that therefore require a lube that will stay in place a long time.

Grease, with its greater viscosity, will do just that. The other major lubricant is oil, which is a liquid state that does not adhere to surfaces, making it a perfect lube. Mineral oils such as petroleum are best for lubrication, because they do not degenerate nearly as quickly as organic oils do. Lubrication systems are employed in almost every industry that uses mechanical equipment.

This includes oilfields, power plants, steel processing companies, the food and beverage industry, printing, mining and industrial manufacturing. The need for lubrication is not specific to these large scale production based industries though; many products that are used everyday by the common middle class American require regular lubrication, including cars and computers.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches