Lubricators apply a controlled amount of lubricant to areas of friction on rotating or moving mechanical parts. Since bearings, dies, chains, cables, spindles, pumps, railways, and gears need to be lubricated for equipment to function smoothly and dependably, lubricating systems are essential to manufacturing and industrial businesses. Read More…

Established in 1997, Acumen Technologies, Inc. has been a trusted manufacturer of a high quality chain oiler for fifteen years. Our experienced employees are very knowledgeable and ready to answer any questions you may have about lubricating products and equipment. We seek to create products that solve lubrication problems you may be having. Contact us today and let us know how we can serve you!

Our grease pumps cannot be topped! Since we were established we have been providing our customers with an extensive line of lubrication systems equipment that will stand up the rigorous wear and tear of everyday application in order to provide a lifetime of value. We have been providing our customers exceptional customer service and this is a tradition that we strive to continue. Visit our...

Automatic lubricating systems, lubrication equipment, bulk grease transfer systems, pumps and other lubricating machinery are available through us. We design and manufacture lubrication systems and make repairs. We distribute specialty lubricants, chain lubricators and other lubrication products.

North American manufacturer and distributor of meters and systems designed for monitoring circulating oil lubrication and grease distribution. Product types include variable area flow meters, oval gear flow meters, grease pumps, dosers and flow sensors. ESKO meters are available in multi-flow configurations of up to 12 meters in a bank. Lubrication monitoring systems can be furnished in custom...

Are you looking for variety and ease in ordering? Then you've come to the right place... D & D Instruments. We offer automotive oil gauges and vacuum gauges. We also provide pressure process gauges. We furnish extensive on-line ordering so you can order just the right product for your application.

More Lubricator Manufacturers

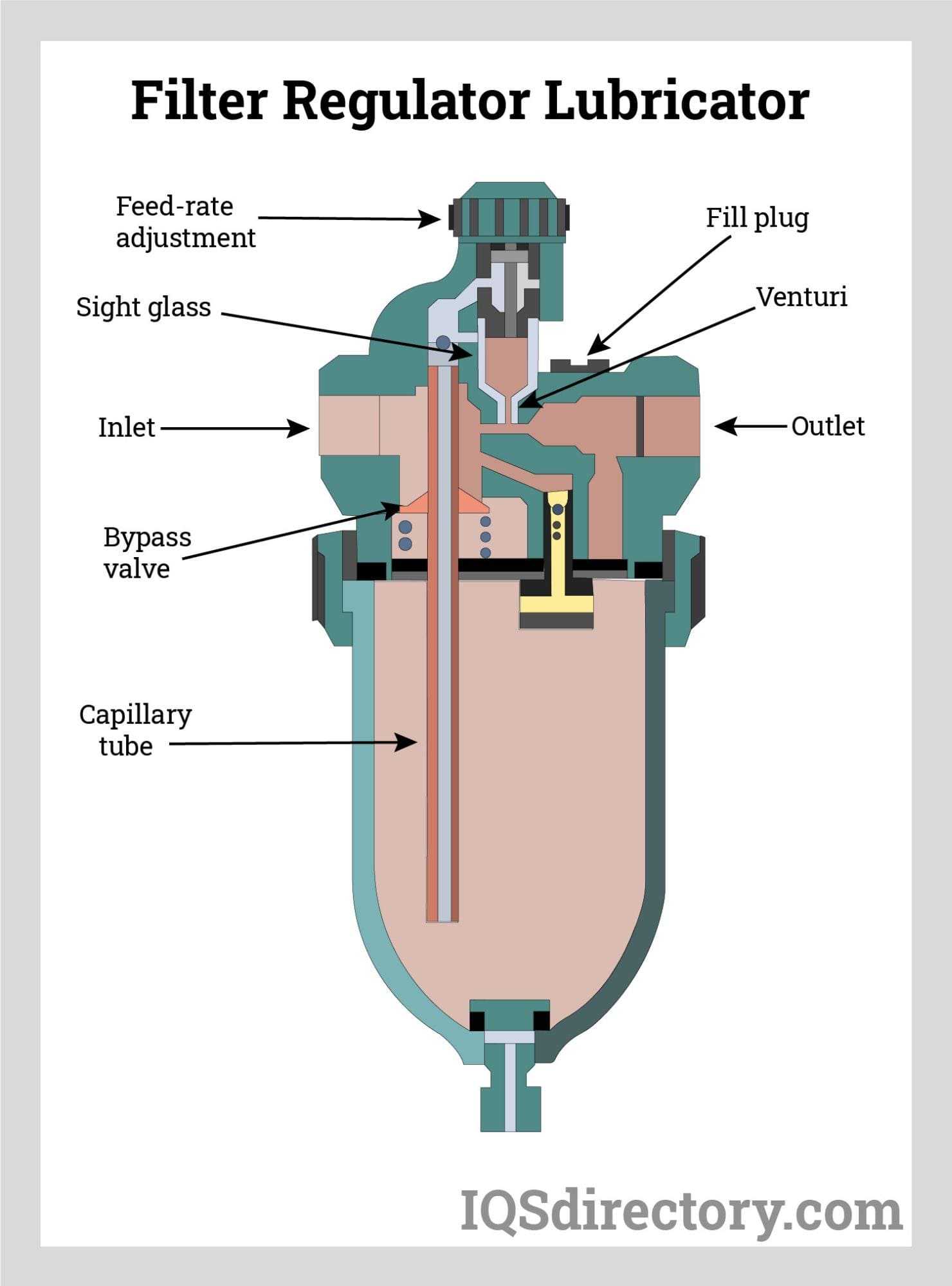

Lubricator Design

The reservoir, pump, and filter are the three major components of lubricating systems. The old lubricant is stored in the reservoir after being consumed and then transferred by the pump to the system's necessary locations for lubrication. The filter keeps the system running smoothly by removing impurities from the lubricant.

Types of Lubrication Systems

Single-line Resistance

A central pump disperses the lubricant to one or more supply lines that are parallel to one another in single-line resistance (SLR) lubrication systems. These oil lubrication systems, which are low-pressure systems, are used for light and medium machines. The range of the oil pressure is 100 to 250 psi. These lubrication systems have a 100-point lubrication capacity. While the machine is in use, the oil flow is carefully controlled and distributed to the necessary machine parts.

Dual-line Lubrication

Dual-line lubrication systems use the two-phase alternating cycle, sometimes called deadline or double-line lubrication systems. The lubricant is injected from the reservoir to the first supply line during the first cycle, which causes all of the injectors' intake and discharge pistons to move in the same direction. Additionally, the lubricant is discharged in one direction. The two supply lines share the injectors, which are set up in a modular fashion.

Positive Displacement Injector Lubrication Systems

A central pump drives positive displacement injector (PDI) lubrication systems, which create pressure (more than 55 bars) to spread the oil throughout several supply lines. After that, the lubricant is applied to the feed lines, where PDIs are mounted. The fixed displacement piston inside the PDIs is moved hydraulically against spring pressure once the operative pressure is attained to discharge a fixed amount of lubricant into the lubrication point. Small- to medium-sized machinery with PDI lubrication systems are used when several lubrication sites must be precisely and accurately dispensed with lubricant. Systems for PDI lubrication can be programmed to release lubricants at predetermined intervals.

Series Progressive Lubrication Systems

The master divider block, which distributes the lubricant to secondary divider blocks, is connected to the pump in a series of progressive lubrication systems. In divider blocks, the necessary lubrication is delivered by several hydraulically operated spool valves organized in a modular fashion. Since the lubricant is dispensed from each valve in series, the lubricant on one valve will release after the discharge of lubricant from the valve before it. As a result, the divider block operates flawlessly if the final valve releases the right amount of oil. But if one valve is broken, the divider block won't disburse the lubricant properly, leading to pressure buildup.

Types of Lubricants

Grease and oil are the typical lubricants released by lubricators, while other lubricants are also available. The semisolid, soap-and-oil-based grease is frequently used in difficult-to-reach spots because it lasts for a long time and only occasionally needs replenishing. Liquid lubricants that are simple to apply but provide essential protection against wear and corrosion for a machine in constant motion are known as oil lubricants. They are frequently mineral-based compounds like petroleum. When lubricants are discarded improperly, they may not all be environmentally sound.

Lubricant Components

Grease Lubricants

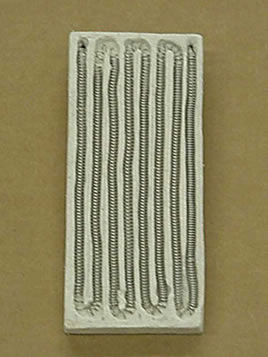

Oil, a thickening agent, and additives with self-lubricating qualities, like PTFE, graphite, and molybdenum disulfide particles, all combine to form grease. Due to their increased stickiness, grease lubricants adhere to surfaces more effectively. They shield the lubricated machine components' surfaces from deterioration and damage.

Dry Lubricants

Small, self-lubricating particles like PTFE, graphite, and molybdenum disulfide make up dry lubricants. When sprayed over the machine part's surface, these particles produce a tiny, slick layer. Dry lubricants can be combined with water, alcohol, or solvent and sprayed together; eventually, the mixture will evaporate, leaving the thin lubricating film on the surface. Dry lubricants do not draw dust or grime, unlike oil and grease.

Dry lubricants are employed for machine parts needing high accuracy, like actuating ball screws, lead screws, and gears. They can be found in hinges, locks, bearings, and threaded rods. Since oils oxidize at high temperatures, they are the greatest choice for high-temperature applications. However, because these lubricants can be wiped away, they are not the best when the lubrication point is exposed to liquids and solvents.

Gear Lubricants

Gear lubricants are made specifically to prevent abrasion on the gears and their gear teeth. These lubricants must be thermally stable to stop sludge buildup on the gears. Gear lubricants can be used with special additives to guard against localized corrosion and pitting on the gear teeth. To protect the surfaces from high pressure during shock loading, certain gear lubricant formulations use extreme pressure (EP) additives; EP additives are necessary for lubricants for gears inside strongly loaded gearboxes.

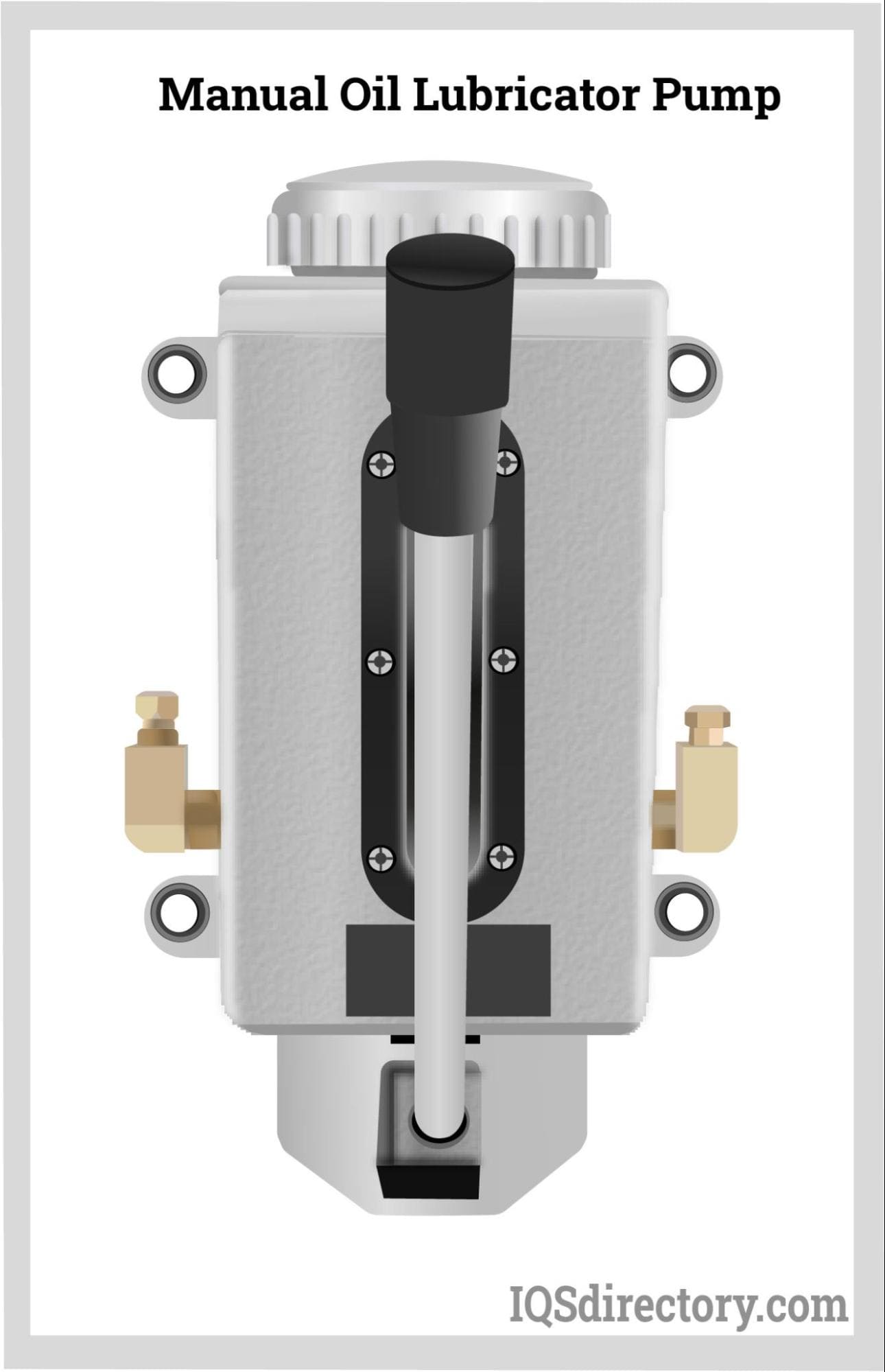

What to Consider When Buying Lubricators

Factors including capacity, pressure, flow rate, and maximum operating temperature should be considered when choosing a lubricating system. There are manual and automatic lubricators. Central lubrication systems (which are connected to the enormous machinery they maintain automatically by preprogramming) are particularly common in large industrial settings. Even though they can be connected to automatic systems like air lubricators, grease pumps are an example of manual lubricators. There is a lubricator to do the job, whether designed for spot lubricating machinery or for keeping a particular item, like a chain, consistently oiled or greased.

Choosing the Correct Lubricators Supplier

To make sure you have the most positive outcome when purchasing Lubricators from a Lubricators Supplier, it is important to compare at least 4 or 5 Suppliers using our list of Lubricators manufacturers. Each Lubricators Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Lubricators business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Lubricators businesses with the same message.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches