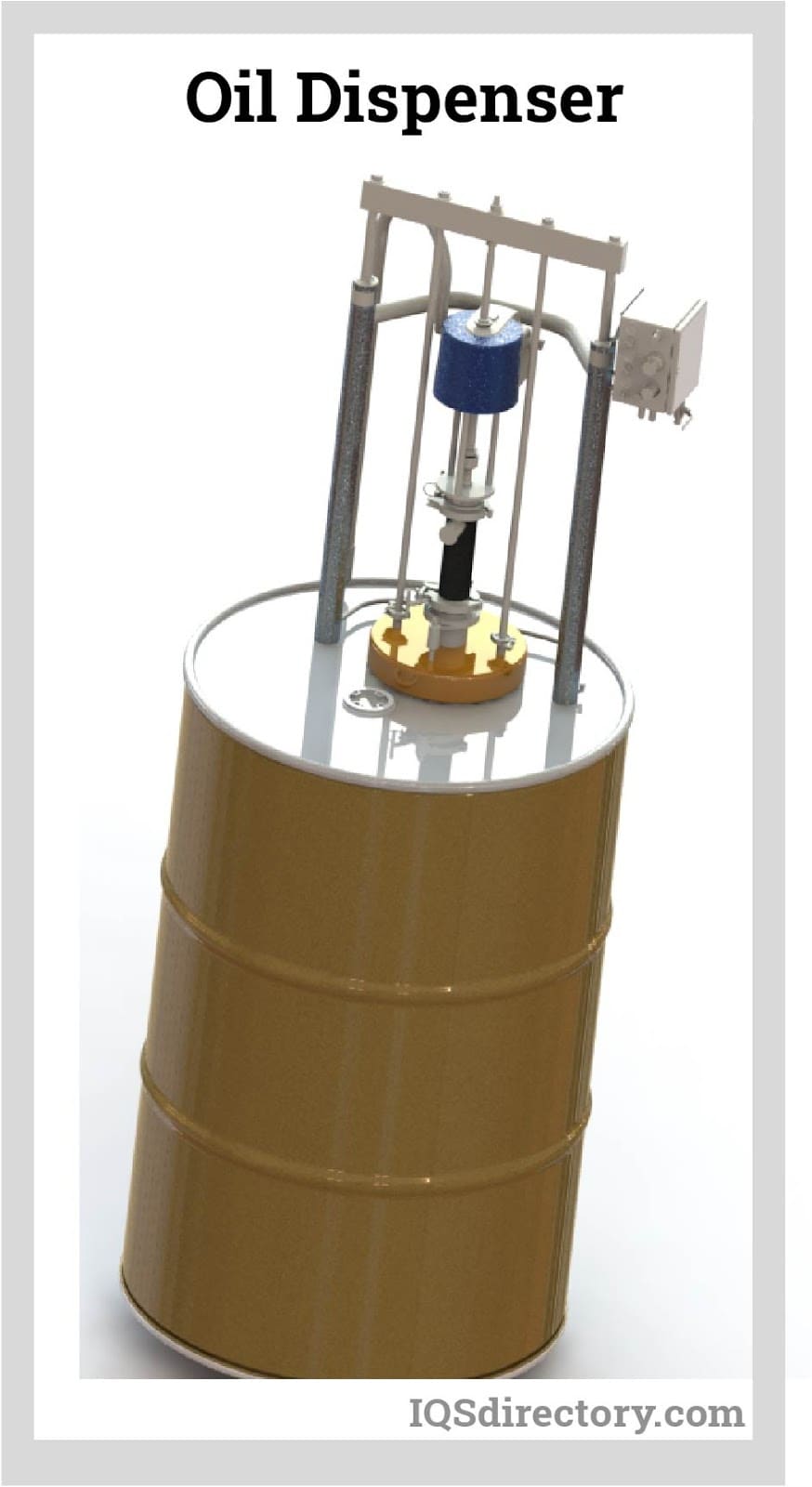

Oil dispensing is a way to store bulk oil in one place. Oil dispensers also help reduce, prevent or eliminate contamination during storage. Lubricants and oils can get contaminated while being delivered and stored. Further contamination can occur with incorrect dispensing and handling. Read More…

Established in 1997, Acumen Technologies, Inc. has been a trusted manufacturer of a high quality chain oiler for fifteen years. Our experienced employees are very knowledgeable and ready to answer any questions you may have about lubricating products and equipment. We seek to create products that solve lubrication problems you may be having. Contact us today and let us know how we can serve you!

Our grease pumps cannot be topped! Since we were established we have been providing our customers with an extensive line of lubrication systems equipment that will stand up the rigorous wear and tear of everyday application in order to provide a lifetime of value. We have been providing our customers exceptional customer service and this is a tradition that we strive to continue. Visit our...

Automatic lubricating systems, lubrication equipment, bulk grease transfer systems, pumps and other lubricating machinery are available through us. We design and manufacture lubrication systems and make repairs. We distribute specialty lubricants, chain lubricators and other lubrication products.

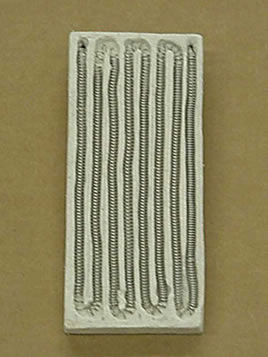

North American manufacturer and distributor of meters and systems designed for monitoring circulating oil lubrication and grease distribution. Product types include variable area flow meters, oval gear flow meters, grease pumps, dosers and flow sensors. ESKO meters are available in multi-flow configurations of up to 12 meters in a bank. Lubrication monitoring systems can be furnished in custom...

Are you looking for variety and ease in ordering? Then you've come to the right place... D & D Instruments. We offer automotive oil gauges and vacuum gauges. We also provide pressure process gauges. We furnish extensive on-line ordering so you can order just the right product for your application.

More Oil Dispenser Manufacturers

Bulk Storage Oil Dispensing Systems

Bulk oil dispensers typically consist of four to eight storage tanks that carry 30 - 240 gallons each. These tanks can be ordered to specific requirements.

Features of Oil Dispensing Systems

There are multiple factors to consider when choosing an oil dispenser or dispensing system for bulk storage. If cross-contamination is a risk in your facility, consider using color-coded tanks that match the same hose and tap. Pressurized taps can help ensure that oil is delivered at the proper flow rate. Manufacturers worried about EPA compliance should consider investing in a spill containment tray or reservoir. The hose should be a quick-connect fire suppression hose and include auto-shutoff and tank isolation valves.

The tanks themselves should be made of polyethylene or stainless steel. They’ll need a pump and a filter for filling, kidney-loop filtration and dispensing. It is recommended to use a positive displacement gear pump with an internal bypass to transport oil without filtering it. Standard beta filters work for an oil distribution system. It’s good practice to place desiccant breathers on each tank while storing bulk oil is the best practice. A bulk oil dispensing system should be adjustable to meet changing requirements. This could entail doing so when more tanks are needed to accommodate different types of oils.

Oil Drum Dispenser

Oil drum dispenser systems should be designed for contamination control and saving space. A tote dispensing rack is made for large-capacity polyethylene totes and functions similarly to oil drum dispensing systems. The pump, hose reel, and filters are positioned beneath the tote, just above the spill containment tray, and the tote is positioned on top of the rack. To satisfy SPCC compliance, the spill containment tray capacity on the tote dispensing rack should be expandable. The features of the tote dispensing rack are similar to those of the oil drum dispensing system.

This system should include a retractable hose reel with a trigger dispenser. The tote dispensing rack should also be compatible with forklifts for easy reorganizing. Oil tote dispensing racks are designed for particular viscosity ratings and can be equipped with various motors.

Benefits of Oil Dispensers

Oil dispensers facilitate economical, safe, and clean oil management. They help prevent expensive spills and clean-ups. Bulk Oil dispensing systems can accommodate many oil storage tanks together, while stackable oil tote dispensing racks can accommodate 300-gallon totes on top of the dispensing system. Oil dispensing systems generally help consolidate an oil inventory. As the inventory changes, they can also be rearranged.

Choosing the Proper Oil Dispensing System Company

To make sure you have the most constructive outcome when purchasing an Oil Dispensing System from an Oil Dispensing System Supplier, it is important to compare at least 4 Companies using our Oil Dispensing System directory. Each Oil Dispensing System Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Oil Dispensing System company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Oil Dispensing System businesses with the same quote.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches